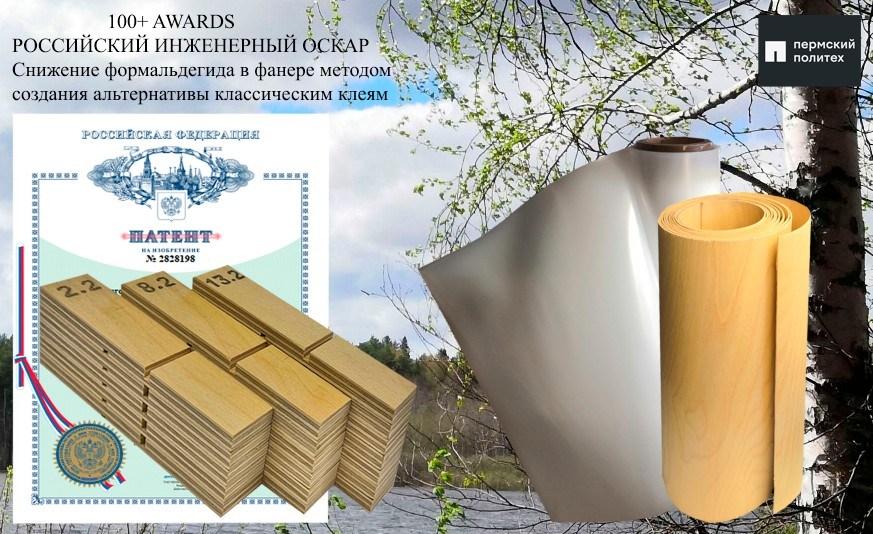

Reduction of formaldehyde in plywood by creating an alternative to classical adhesives | Palkin V.G. (PNRPU)

General-purpose plywood is produced in Russia, while relatively inexpensive thermosetting formaldehyde adhesives are used as adhesives, which contain the formaldehyde substance in the free state. When such adhesives cure, the formaldehyde content decreases, but nevertheless, in a certain concentration, it remains in the cured product and is released into the surrounding space.

As an alternative to formaldehyde adhesives, it is proposed to use such a common polymer material as polyethylene.

The study of plywood products consists of two main areas:

- Firstly, these are physico–mechanical tests, one of the main tasks of which is to determine the adhesive properties of polyethylene film adhesives to wood veneer;

- Secondly, chemical tests to determine the emission class for the release and content of formaldehyde.

Specialists of the Department of Construction Engineering and Materials Science of Perm National Research Polytechnic University (PNRPU) propose a method for establishing the adhesion of surface layers of polyethylene to wood, consisting in distributing modifying additives onto polyethylene film, followed by laying it between sheets of wood veneer and further hot pressing (RF Patent for Invention No. 2828198). This method reduces the consumption of modifiers, while the strength characteristics of the product comply with the requirements of regulatory documents.

To date, a number of tests of plywood on polyolefin film adhesives have been carried out.