Non-removable formwork for monolithic slabs | Sibform LLC

SP 430.1325800.2018 (n 5.2.12) Monolithic structural systems (formerly SP 52-103-2007 "Reinforced concrete monolithic structures of buildings" (p.7.8) recommends the use of hollow inserts in monolithic floors of buildings.

The main function of the non—removable formwork is to lighten the slab. The concrete of the median zone and the supporting frames for the upper reinforcement, which do not participate in its work, are removed from the overlap, thereby reducing the consumption of monolithic reinforced concrete (concrete, reinforcement) as well as time and labor costs. This has a positive impact on all building structures and engineering systems by making them easier and cheaper.

Hollow formers can be used in all types of buildings and structures with a monolithic frame to significantly reduce the dead weight of slabs and save building materials.

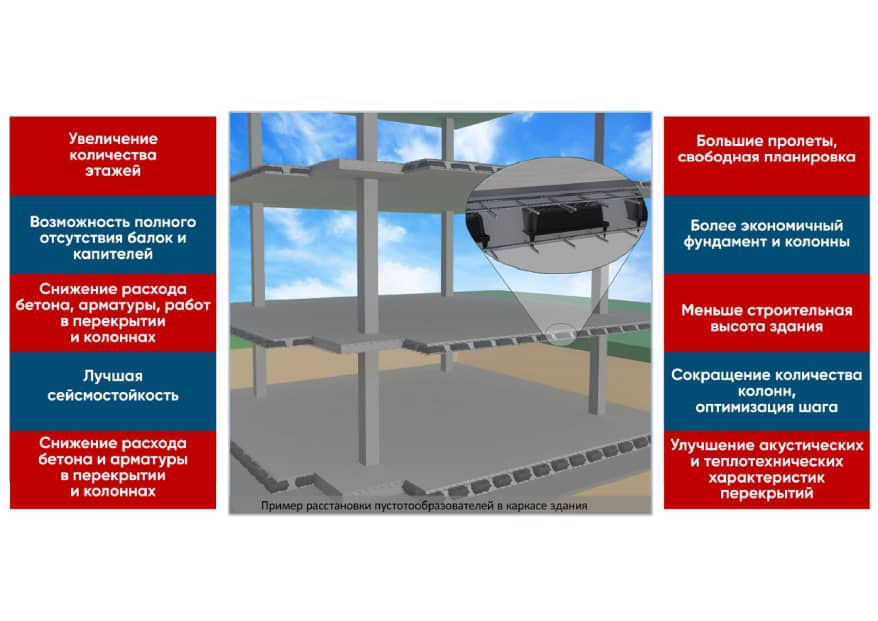

The main advantages of Sibform technology are:

- Reducing the weight of slabs and, as a result, the consumption of concrete, working and structural fittings, including in columns and foundations.

- The ability to increase the span of slabs without the use of beams, capitals, etc., optimize the pitch and number of vertical load—bearing structures - columns, pylons, walls. This simplifies the design and construction of buildings and structures.

In general, the introduction of this method leads to a reduction in the estimated cost of construction. On average, with the proper use of technology, savings on a monolithic building frame amount to 10%. In slabs, the reduction in the consumption of concrete and reinforcement reaches 30% (the average value is about 20-25%), in columns and foundations — up to 10%.

Reducing the dead weight of the building floor slabs is one of the main factors affecting the overall earthquake resistance and consumption of reinforced concrete on the main load-bearing structures. With our technology, it is possible to build reliable buildings in earthquake-prone areas while reducing the cost of the supporting frame.

The positive impact of Sibform technology on the speed of construction is due to the following factors:

- Reducing the volume of recycled building materials. Up to 30% less concrete and metal must be taken, moved upstairs, processed and laid.

- Supporting frames in reinforcement are excluded. They are, in fact, replaced by void formers.

The use of Sibform technology also has a positive impact on the environment. We use recycled thermoplastics as raw materials, which is a positive property of this technology from an environmental perspective, since the reuse of plastic significantly reduces environmental pollution.

Among the iconic facilities where Sibform products are used, it is worth mentioning the G3 high-rise tower in Yekaterinburg City, a unique residential complex on the territory of the Badaevsky brewery in Yekaterinburg. Moscow, civil office of Rosatom Corporation in Moscow Moscow, office and business building in Savings City, Moscow, residential area "Lesnaya Polyana" in the suburbs Astana, Kazakhstan.