The technology of building enclosing structures using hinged three-layer wall panels and facade modules | PREFAB TECHNOLOGIES LLC

The technology of building enclosing structures using hinged three-layer wall panels and facade modules | PREFAB TECHNOLOGIES LLC

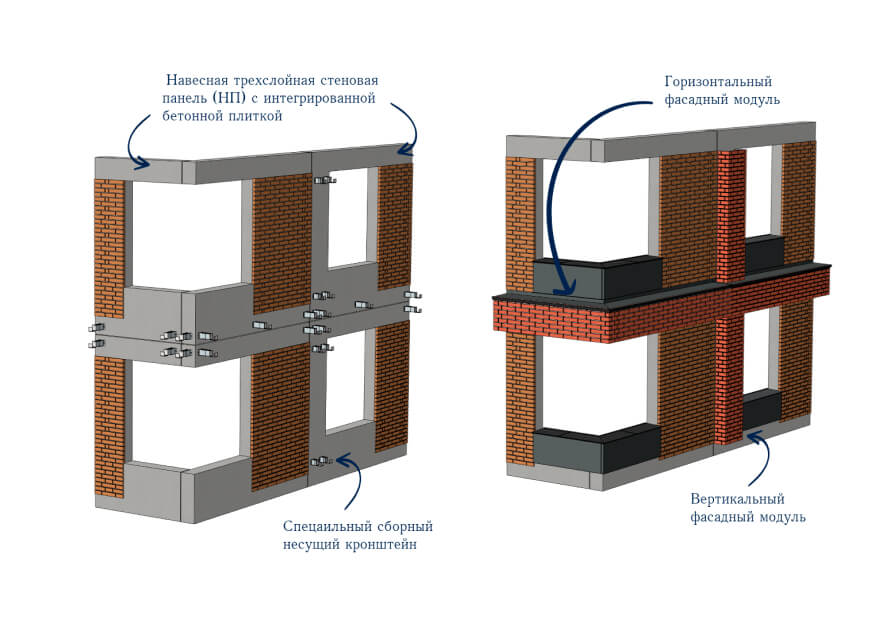

The innovation of the technology consists in the use of a combined solution of hinged three-layer wall panels according to GOST 32603-2021 with various exterior finishes (ceramic or concrete tiles, bricks) and individual factory-made facade modules to create a special architectural appearance of the facade, accelerate installation and ensure the quality of the facade solution by increasing industriality.

The installation of external enclosing structures of buildings using NP together with facade modules not only includes all the advantages and advantages of the technology of a hinged ventilated facade, but also eliminates its disadvantages.:

- The human factor in making mistakes during the installation of the system is minimized, and there is also no need to involve highly qualified installation workers.;

- thermal insulation is arranged inside the NP, which removes the need for a wind and moisture barrier membrane, and also increases the thermal performance of the system by eliminating "cold bridges";

- The factory assembly of the modules allows for high-quality fastening of facade materials with precise joint positioning while simulating piecemeal assembly.;

- specification of the positioning of the attachment points of the facade modules to the building base due to the preliminary calculation of the load-bearing capacity of the structure and the subsequent installation of embedded couplings installed in the outer layer Inventory item in the factory at the time of its forming;

- reducing the time required for the installation of enclosing structures and high-quality connections between each other (most of the most time-consuming facade assembly processes have been transferred to factory production, which makes it possible to achieve the installation speed of one module with an area of up to 3 square meters. m together with its adjustment in no more than 12 minutes).

From a technical point of view, facade modules are prefabricated architectural elements of the facade. They are installed by hanging them on pre-installed and factory-assembled brackets.

Slinging and lifting of modules is performed using slings with shorteners and a universal gripper, which is equipped with locking elements with locking mechanisms to prevent spontaneous unloading of cargo.

After the module is installed in the design position, it is adjusted. The technology allows you to adjust the structure in height and relative to the building base at a distance of up to 35 mm.

The overall dimensions of the prefabricated architectural elements of the facade make it possible to realize a wide variety of creative ideas of architects, and also do not forget the three main axioms of design: safety, reliability and durability.

The reliability of the first-time applied structural and technological solutions of prefabricated architectural elements together with NP is confirmed by the necessary laboratory tests and calculation justifications.

An important advantage of the technology is its economic efficiency:

- High facade construction rate (8.3 times faster than standard NSF technology);

- Due to the imminent closure of the building's thermal circuit, it is possible to attract a larger number of potential home buyers.;

- The ability to hire smaller installation units to perform the same amount of work (the facade module is installed by 2-3 installers);

- High quality and correct assembly of the structure, which reduces the possibility of defects and ensures a workable technical condition of the facade during the estimated service life.