Development of a method for combining precast concrete slabs and steel beams | Creative team

DEVELOPMENT OF A METHOD FOR COMBINING PRECAST REINFORCED CONCRETE SLABS AND STEEL BEAMS. EXPERIMENTAL AND THEORETICAL RESEARCH

The author's team: Konin D.V., Kaprielov S.S., Buchkin A.V., Krylov A.S., Rozhkova L.S., Rtishcheva I.V., Chilin I.A., Igolnikov I.S.

Floors with prefabricated slabs laid on steel beams are used in the construction of residential and public buildings, parking lots, and industrial structures. Currently, existing methods in the Russian Federation and the world for combining steel and precast reinforced concrete (using bolts and welded joints) are quite laborious and require special equipment. It was necessary to come up with a node that would require minimal labor during installation, a minimum (or no) specialized fasteners, a minimum of "wet" processes and welded joints. Currently, floors with prefabricated slabs are widely used, but they are constructed without combining steel and concrete due to the lack of reliable experimental data.

Technical solutions for the assembly of steel-reinforced concrete structures with prefabricated multi-cavity slabs and steel beams have been developed based on a significant amount of experimental and theoretical research, analysis of world and Russian experience. More than 25 models of structures have been tested, including 5 full-size models of floors measuring 10×6 m in various configurations by loading sandbags with a total weight of more than 70 tons from above.

The priority task of the research was to ensure the joint operation of prefabricated structures based on simple structural solutions — additional anchor rods, flexible stops and small monolithic sections of self-sealing non-shrinkable concrete mixtures of normal and increased strength. The tasks were completed. Based on experimental and theoretical studies, the following layout options for prefabricated slabs with steel beams have been proposed.

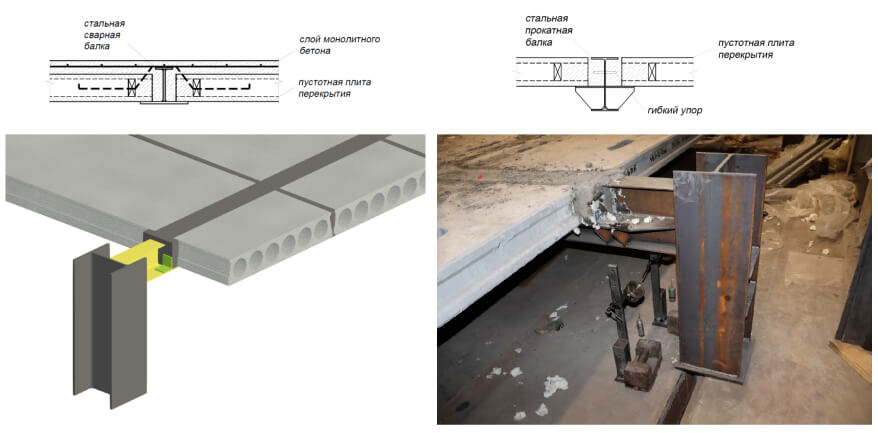

- The plates are laid on the lower shelves of metal I-beam welded beams. To ensure the joint operation of reinforced concrete slabs with steel beams, angle stops were installed for the outermost slabs to prevent horizontal displacements during loading, as well as partial sealing of voids in the slabs. Reinforced concrete 80 mm thick is laid on top of the slabs. The design diagram is shown in Figure 1. Such an overlap can be used in residential and public buildings where it is necessary to design structures of minimum height.

- The floor slabs are laid on the support platforms of metal beams, the upper surface of the slabs coincides with the upper shelf of the beam. To ensure the joint operation of reinforced concrete slabs with steel beams, flexible stops were welded to the wall of the beams, as well as the installation of thrust corners for the outermost plates to prevent horizontal displacements during loading; partial sealing of voids in the plates was performed. The design diagram is shown in Figure 2. Such floors can be used in structures with significant loads (parking lots, industrial sites, warehouses).

The use of precast reinforced concrete structures in the proposed variants will make it possible to use all the advantages of precast reinforced concrete slabs (factory manufacturing involves precise geometric dimensions, minimizing defects and additional factory control of the product; quick installation is ensured on the construction site by reducing reinforcement and concrete work) and the advantages of reinforced concrete structures (due to the competent cross-sectional layout and distribution of forces between steel and concrete provides a high load-bearing capacity of the elements while reducing the material consumption of the structure as a whole). Steel savings when combining a beam and a prefabricated plate can reach up to 25%. At the same time, additional hardware (stud bolts) does not appear, standard plates can be used without additional embedded parts, made by continuous molding.

The proposed layout options for prefabricated slabs with metal I-beams make it possible to reduce the construction height of the floors. In addition, they promote the popularization and expand the range of applications of metal structures in the Russian Federation, which meets the needs of the metallurgical industry in conditions of limited export markets.

It should be noted that the use of precast reinforced concrete in the proposed version will reduce construction time, save materials, and ensure durability and safety of operation with proper quality control.

The work was carried out at SIC Stroitelstvo JSC with the support of the Association for the Development of Steel Construction, which unites the largest Russian metallurgists (EVRAZ, OMK, NLMK, Severstal, etc.).