PropTech.SMC | Proptech LLC

PRODUCT DESCRIPTION

PropTech SMC is a solution for digitalizing the concreting process based on the Internet of Things and a time—reduction service. PropTech SMC reduces the time required for monolithic work by up to 20%. At the moment, software has been developed for monitoring the temperature, strength and maturity of concrete and hardware version 2.0 with the possibility of reuse of devices. In 2021, specialists with experience as chief designers, authors of scientific articles, and current members of Russian and international concrete associations created a product that successfully passed 3 pilot tests and began its first sales. More than 150 sensors have been purchased by current customers. The solution became a finalist in the open selection of innovative products of the CCCC GC Rosatom was founded in December 2021 and was included in the top 40 projects of the Skolkovo 2021 BuildUP. PropTech SMC employees participated in an online meeting of the Guild of Organizations of the MTPP Construction Complex and other events on the topic of innovations in construction.

This year, we plan to implement industrial production of sensors based on domestic components and enter industrial construction. Potentially, we want to cover 1% of the market from 30 million cubic meters in the short term.

THE SOLVED PROBLEM OF THE CLIENT

Potential clients are Players in the construction market, including concrete strength testing laboratories.

Types of construction: Commercial and office construction, residential apartment construction, industrial construction, residential housing, road construction.

The problem:

- There is no objective data on concrete quality control at the moment.

- There is a market need for tools to reduce the production time of concrete works

- The complexity of concreting quality control

- Low level of staff responsibility

- Shortage of qualified personnel

- Unpredictable quality level of monolithic structures

- Forced reserves of time for concrete strength gain

technology

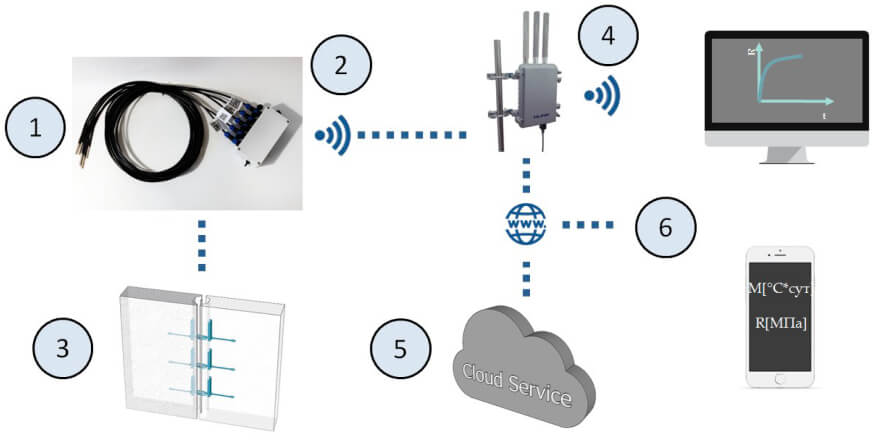

The solution consists of :

- digital temperature sensors;

- logger module with data transmission unit via Wi-Fi radio channel

- 4G Wi-Fi hotspot

- cloud service (PropTech.SMC software)

The sensors are mounted on the facility. Data is transmitted over the Wi-Fi channel, data is entered into the system automatically, graphs are plotted based on the received data and information is displayed in the software. The client's access to the product is carried out via the Internet from a desktop computer or laptop/tablet from a browser, and through a mobile application installed on a smartphone.

Basic functionality:

- Remote online monitoring

- Online temperature control of concrete

- Alerts and notifications about construction processes

- Online forecast of concrete set time for a given strength

- Automatic release of executive documentation (ID)

Benefits of PropTech.SMC implementation:

- reduction of construction time due to early confirmation of the required concrete strength

- online quality control of concrete

- availability of data acquisition from any Internet-connected device (IIoT solution)

- reduction of time and labor costs in the preparation of executive documentation

- the ability to fill a digital building model with objective data from online concrete monitoring

- mobility and speed of decision-making in terms of retention/demoulding of monolithic structures

- cost reduction during winter concreting (1 day of concrete heating — from 500,000 rubles)

Economic effect:

- Reducing losses and accelerating the pace of construction 20%

- 3-4 months of saving construction time

- Up to 50% cost savings on concrete work

Reduction of construction time by 3-4 months as a result of the transition to the next stage at 70% strength, rather than according to time standards, and up to 50% cost savings on concrete work by reducing warm-up time and reducing the number of tests, reducing the number of employees, and prompt decision-making on demoulding structures or removing the greenhouse.

The effect of the technology application:

- Reduction of construction time,

- Improving the quality of monolithic works

- Cost savings on concrete work

- ESG — Reduction of carbon footprint and reduction of energy consumption